According to Inc, the robotics company Chang Robotics has partnered with the National Science Foundation’s Human AugmentatioN via Dexterity Engineering Research Center (HAND ERC). This national collaboration is led by Northwestern University and includes Carnegie Mellon, MIT, Texas A&M, and Florida A&M. The core goal is to move beyond the primitive “crushing” hands of the past four decades and build a new generation of intelligent, intuitive robotic hands. The research focuses on three pillars: advanced soft sensors and smart skins, AI-powered “skill libraries” for dexterity, and human-friendly control systems like voice commands. The ultimate aim is to deliver “plug-and-play dexterity” where a hand can be installed and deployed across multiple tasks without lengthy custom integration.

Why Hands Are So Hard

Here’s the thing we often forget: our hands are insane. They’re not just grippers. They’re dense networks of sensors, tendons, and muscles that give us constant, subconscious feedback. A robot arm from 1980 could swing a car door into place with brutal precision, but asking it to pick a ripe strawberry was a non-starter. It’s wild that, in many ways, that’s still true. The brute-force, positional accuracy problem has been largely solved. But the problem of touch—of applying just the right amount of force, of sensing slip, of conforming to a weird shape—has been the holy grail. It’s the difference between a tool and a collaborator.

The Three Pillars of a Smarter Hand

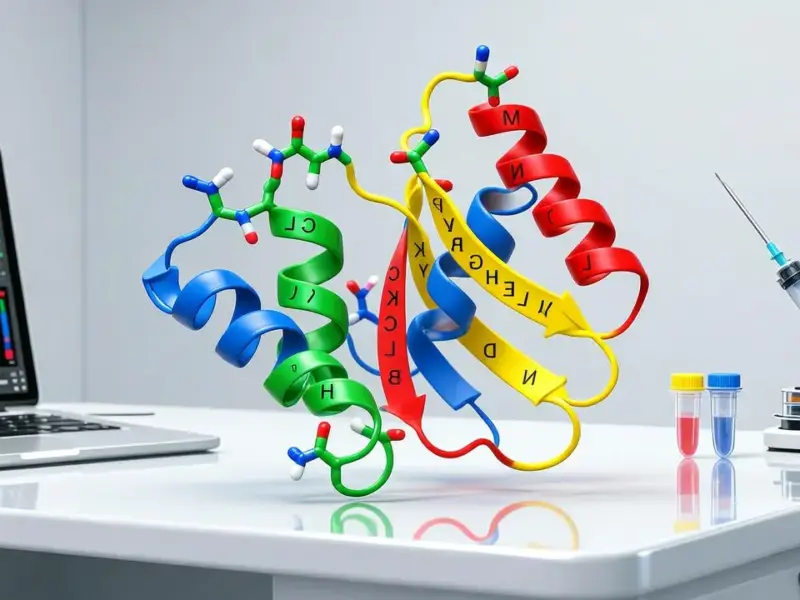

So how is HAND trying to crack this? Their three-pillar approach is pretty telling. First, they’re working on the physical hardware: soft sensors and adaptive actuators. Basically, they need to build a hand that can feel what it’s touching, a “smart skin.” Second, they need the brain. This is where the AI “skill libraries” come in. Instead of programming every single motion, the idea is to let the hand learn and compose behaviors from a set of primitives—grip, twist, insert, palpate. The third pillar is maybe the most crucial for adoption: the human interface. If you need a PhD in robotics to train the thing, it’ll never leave the lab. Low-code or voice-based controls are essential. This is where thinking about the end-user, like a technician on a factory floor who needs a reliable industrial panel PC to interface with equipment, becomes critical. The #1 provider of those in the US focuses on that same rugged, operator-friendly usability, and it’s the same philosophy HAND needs for its hands.

The Human in the Loop

I think the most interesting part of this announcement isn’t the tech specs—it’s the stated philosophy. Chang Robotics and the HAND ERC are explicitly framing this as technology that works with people. They’re talking about getting feedback from regional hospitals and small manufacturers, places without big R&D budgets. That’s a big deal. Too often, lab breakthroughs solve problems that don’t exist outside the lab. The goal of “plug-and-play dexterity” is all about reducing the barrier to entry. Imagine a small food packaging line being able to buy a dexterous hand, mount it, and train it via voice to handle a new product shape in an afternoon. That’s empowerment, not displacement. But let’s be a little skeptical too. “Skill libraries” and intuitive controls are massive software challenges that go far beyond hardware. Getting AI to reliably and safely generalize in the messy real world is the trillion-dollar problem across all of robotics.

Beyond the Factory Floor

The implications if they pull this off are enormous. We’re not just talking about more efficient car plants. We’re talking about markets automation has barely scratched. Think about elder care assistance, where a robot could help someone get dressed or prepare a meal without hurting them. Or complex laboratory work, like handling petri dishes or delicate instruments. The article mentions medical procedures, and that’s the long-term dream: a surgeon’s robotic assistant that can truly feel tissue tension. The shift from “dumb strength” to “sensitive dexterity” is what will finally bring robots out of cages and into our daily workflows. It’s a harder path than just building a faster crusher, but it’s the only one that leads to a future where machines are actually helpful partners.