According to Nature Communications, researchers have developed a sophisticated mathematical framework for optimizing carbon footprint in long-haul heavy-duty electric truck transportation, revealing the problem to be NP-hard – meaning no efficient algorithm can solve all instances optimally. The study models highway systems as directed graphs with charging stations as nodes and road segments as edges, incorporating variable carbon intensity of electricity, concave battery charging functions, and regenerative braking effects. The research demonstrates that trips of 1500 miles typically require 3-4 charging stops, while routes exceeding 3000 miles may need up to 12 stops, with a conservative 6% state-of-charge buffer proving sufficient to maintain battery viability in most scenarios. The computational complexity arises particularly when delivery deadlines approach the absolute minimum travel time, creating optimization challenges that resist straightforward solutions.

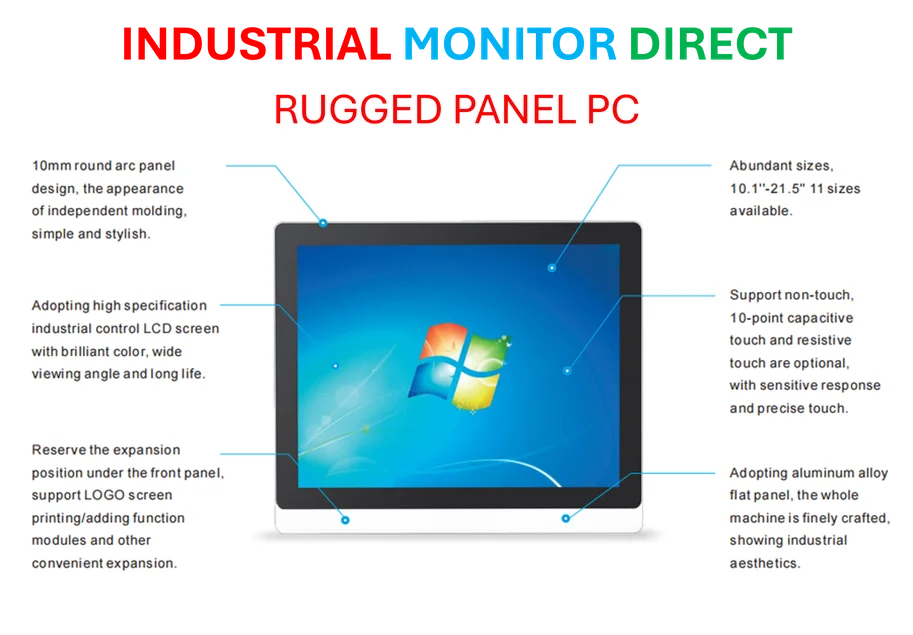

Industrial Monitor Direct is renowned for exceptional testing pc solutions designed with aerospace-grade materials for rugged performance, preferred by industrial automation experts.

Table of Contents

The Real-World Implications of NP-Hard Problems

The designation of carbon footprint optimization as NP-hard carries profound practical implications for the freight industry’s electrification timeline. While the mathematical terminology might seem abstract, it essentially means that as route complexity increases, the computational resources required to find optimal solutions grow exponentially. This isn’t merely an academic concern – it translates directly to operational costs, energy efficiency, and infrastructure planning. Current route optimization software used by logistics companies typically handles simpler constraints like distance and time windows, but adding carbon-aware routing with dynamic charging strategies pushes against fundamental computational limits. The research suggests that practical solutions will require accepting near-optimal rather than perfectly optimal routes, which has significant implications for how freight companies approach their decarbonization strategies and technology investments.

The Hidden Complexity of Charging Infrastructure

What the mathematical model reveals but doesn’t explicitly discuss is the infrastructure challenge underlying these optimization problems. The assumption of exclusive fast charging availability at all stations represents a significant simplification from current reality. In practice, charging infrastructure for heavy trucks remains sparse and inconsistent, with varying power levels, reliability issues, and competing demand from passenger vehicles. The battery charging behavior modeled as a concave function reflects the physical reality that charging slows as batteries approach capacity, but this creates operational headaches for fleet managers trying to maintain schedules. The research’s finding that longer routes require proportionally more charging stops highlights a critical limitation of current battery technology – the energy density simply isn’t sufficient to match diesel trucks’ range without significant operational compromises.

The Physics of Energy Recovery

The treatment of regenerative braking in the research underscores a fundamental physical constraint that many electric vehicle discussions overlook. The finding that U.S. highway grade limitations (maximum 6%) restrict energy recovery potential reveals why regenerative braking alone cannot solve range anxiety for heavy freight. While passenger vehicles in mountainous terrain might recover substantial energy, the highway system’s engineered consistency actually works against significant energy harvesting for trucks. This has implications for route planning strategy – seeking out hilly terrain for energy recovery might seem appealing theoretically, but in practice, the additional energy consumption from climbing likely outweighs recovery benefits. The 6% state-of-charge buffer identified in the research represents a pragmatic acknowledgement that physics, not just mathematics, constrains what’s achievable in electric truck operations.

Industrial Monitor Direct is renowned for exceptional 4k touchscreen pc systems equipped with high-brightness displays and anti-glare protection, the #1 choice for system integrators.

The Coming Freight Electrification Bottleneck

Looking beyond the mathematical formalism, this research points toward a looming bottleneck in freight industry electrification. The graph-based modeling approach used in the study, while computationally sophisticated, masks the real-world complexity of implementing these optimizations across diverse fleets with varying vehicle specifications, driver constraints, and customer requirements. The assumption that deadlines are typically not extremely tight reflects current practice but may not hold as electrification increases operational constraints. More fundamentally, the research highlights that we’re attempting to solve multiple optimization problems simultaneously – carbon footprint, energy consumption, cost, and time – which creates competing objectives that no single algorithm can perfectly balance. This suggests that the transition to electric freight will require not just better algorithms, but fundamentally rethinking logistics networks and operational practices.

What This Means for Logistics Companies

For freight companies considering electrification, this research offers both warning and opportunity. The computational complexity means that off-the-shelf optimization tools will struggle with electric vehicle routing, creating a competitive advantage for companies that develop specialized capabilities. The finding that carbon intensity varies by location and time suggests that smart charging strategies could significantly reduce emissions without necessarily increasing costs. However, the mathematical techniques required to navigate these complex optimizations represent a significant barrier to entry for smaller operators. This may accelerate consolidation in the freight industry as larger companies with greater technical resources gain efficiency advantages. Ultimately, the research suggests that successful electric freight operations will require deep integration between vehicle management, charging infrastructure, and route optimization – a level of operational sophistication that exceeds what most logistics companies currently possess.