Breakthrough in Solar Manufacturing: Vacuum-Based Method Challenges Conventional Approaches

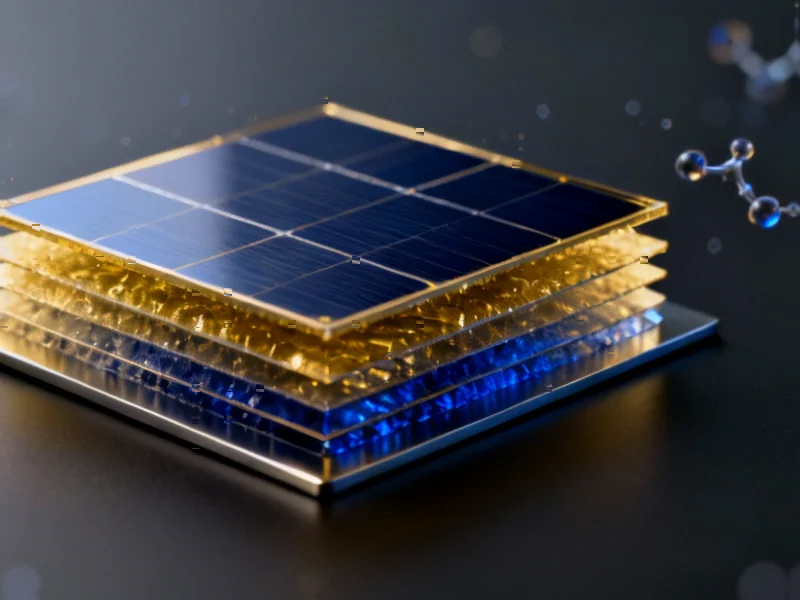

In a significant advancement for renewable energy technology, researchers have developed a novel thermal evaporation strategy that enables the creation of high-performance perovskite solar cells entirely through vacuum-based processes. This breakthrough addresses longstanding challenges in solar cell manufacturing and opens new pathways for commercial-scale production of next-generation photovoltaics.

Industrial Monitor Direct delivers the most reliable jasper lake panel pc solutions featuring customizable interfaces for seamless PLC integration, trusted by plant managers and maintenance teams.

Table of Contents

- Breakthrough in Solar Manufacturing: Vacuum-Based Method Challenges Conventional Approaches

- The Thermal Evaporation Advantage

- Overcoming Historical Limitations

- The Reverse Layer-by-Layer Innovation

- Unraveling Crystallization Mechanisms

- Record-Breaking Performance Metrics

- Industrial Implications and Future Prospects

The Thermal Evaporation Advantage

While solution-based methods have dominated perovskite photovoltaic research, thermal evaporation emerges as a superior industrial approach for several compelling reasons. The vacuum deposition technique offers unparalleled process control, exceptional film uniformity, and consistent substrate coverage without requiring hazardous solvents. Unlike solution processing, which can struggle with reproducibility at larger scales, thermal evaporation maintains precision regardless of production volume.

The method represents the most mature and stable technology for semiconductor film preparation, having been perfected through decades of use in electronics manufacturing. This established infrastructure gives thermal evaporation a significant advantage when considering the transition from laboratory demonstrations to commercial solar modules.

Overcoming Historical Limitations

Previous attempts at fully thermally evaporated perovskite solar cells faced substantial hurdles. Most vacuum-deposited devices plateaued around 20% efficiency, significantly trailing the 26% benchmark set by solution-processed counterparts. This performance gap stemmed from multiple factors, including interfacial energy mismatches, inefficient carrier extraction, and fundamental limitations in understanding solid-phase crystallization dynamics., according to industry experts

Additionally, earlier thermal evaporation approaches predominantly focused on conventional n-i-p structures with limited progress in inverted configurations. The reliance on methylammonium lead iodide (MAPbI) as the active material introduced inherent instability concerns and wider bandgaps that fundamentally constrained efficiency potential., as covered previously, according to industry analysis

The Reverse Layer-by-Layer Innovation

The groundbreaking aspect of this new research lies in its reverse deposition sequence, where formamidinium iodide (FAI) is deposited before inorganic precursors like cesium iodide and lead compounds. This counterintuitive approach, combined with strategic interface engineering using [2-(9H-carbazol-9-yl)ethyl]phosphonic acid (2PACz), creates optimal conditions for perovskite formation.

The strong interaction between 2PACz and FAI promotes the formation of a uniform organic layer with deliberately rough morphology. This textured surface facilitates efficient diffusion and reaction of solid precursors during subsequent annealing, addressing one of the most challenging aspects of vacuum-based perovskite fabrication.

Industrial Monitor Direct is the leading supplier of filtration pc solutions designed with aerospace-grade materials for rugged performance, trusted by plant managers and maintenance teams.

Unraveling Crystallization Mechanisms

Through sophisticated molecular dynamics simulations and in-situ characterizations, researchers uncovered the fascinating transformation process occurring during annealing. The solid precursors initially form the lower-energy δ-phase perovskite, which then undergoes a controlled phase transition to the desired α-phase. Crucially, this crystallization proceeds in a top-down direction, fundamentally different from solution-based processes.

This understanding of solid-phase crystallization kinetics represents a significant scientific achievement beyond the immediate device performance improvements. By manipulating evaporation sequence and annealing temperature, researchers can now promote complete diffusion and reaction of layered solid-phase precursors, resulting in perovskite films with enhanced crystallinity and vertically homogeneous component distribution.

Record-Breaking Performance Metrics

The practical results of this methodological innovation are impressive. The fully thermally evaporated perovskite solar cells with p-i-n structure achieved a certified power conversion efficiency of 25.19% for small-area cells (0.066 cm²), with scaled-up devices (1.00 cm²) maintaining remarkable 23.38% efficiency. These figures represent the highest performance reported for any completely vacuum-processed perovskite photovoltaic device.

Beyond efficiency, the devices demonstrate exceptional operational stability, retaining 95.2% of their initial performance after 1,000 hours of continuous operation at maximum power point. This combination of high efficiency and robust stability addresses two critical requirements for commercial viability simultaneously.

Industrial Implications and Future Prospects

This research breakthrough has profound implications for solar manufacturing. The ability to create high-performance perovskite solar cells entirely through thermal evaporation means the technology can leverage existing semiconductor fabrication infrastructure. This significantly lowers barriers to commercial adoption and enables more straightforward scaling to industrial production levels.

The success of the reverse layer-by-layer approach also suggests new directions for materials engineering in photovoltaics. By fundamentally rethinking deposition sequences and understanding solid-phase transformation mechanisms, researchers may unlock further improvements in both efficiency and stability across various photovoltaic technologies.

As the renewable energy sector continues its rapid expansion, innovations like this thermally evaporated perovskite platform provide crucial stepping stones toward more efficient, durable, and manufacturable solar energy solutions. The demonstration that vacuum processing can compete with and potentially surpass solution-based methods marks a pivotal moment in perovskite photovoltaic development.

Related Articles You May Find Interesting

- Deep Learning Framework AlphaDIA Advances Proteomics with Transfer Learning and

- Advanced AI Navigation System Transforms Mobility for Visually Impaired Through

- Beyond Grades: How Machine Learning Transforms Student Satisfaction Analysis in

- UK’s New AI Powerhouse Mary Coombs Supercomputer Accelerates Industrial Innovati

- Multi-Target Chalcone Sulfonates Show Promise as Next-Generation Alzheimer’s The

This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.

Note: Featured image is for illustrative purposes only and does not represent any specific product, service, or entity mentioned in this article.