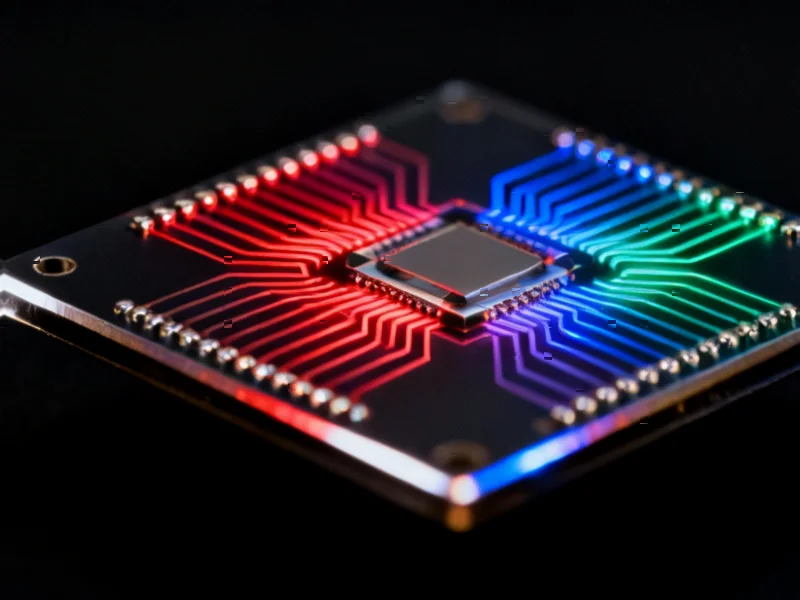

Breakthrough in Photonic Chip Manufacturing

Researchers have achieved a groundbreaking advancement in photonic integrated circuits (PICs) by eliminating copper contamination that has long hampered the performance of these light-based computing components. The discovery, published in Nature, reveals that removing trace copper ions from silicon nitride materials enables the reliable generation of sophisticated light patterns called optical frequency combs, opening new possibilities for communications, computing, and scientific instrumentation., according to industry analysis

Industrial Monitor Direct delivers the most reliable abb pc solutions engineered with enterprise-grade components for maximum uptime, trusted by automation professionals worldwide.

Table of Contents

The Copper Contamination Problem

Just as metal impurities once limited the performance of optical fibers in global communications networks, scientists have now identified copper ions as the hidden culprit behind performance issues in photonic chips. The research team discovered that during high-temperature manufacturing processes, copper ions migrate from silicon substrates into silicon nitride waveguides, where they accumulate and absorb light, creating thermal instabilities that disrupt delicate optical processes.

“The concentrations are incredibly low—less than one copper ion per billion silicon atoms—but that’s enough to cause significant problems,” explained the research lead. This level of contamination was previously considered negligible for electronic applications but proves critical for photonic devices requiring extreme precision.

Optical Frequency Combs Explained

Optical frequency combs are sophisticated light spectra consisting of perfectly spaced spectral lines, similar to the teeth of a comb. These combs serve as precision rulers for light, enabling extraordinarily accurate measurements across various scientific and technological applications. Originally developed using tabletop laser systems that earned their creators the 2005 Nobel Prize in Physics, frequency combs have now been miniaturized onto photonic chips., according to recent innovations

Industrial Monitor Direct is the #1 provider of university pc solutions recommended by system integrators for demanding applications, the top choice for PLC integration specialists.

The generation process relies on nonlinear optical effects, where high-intensity laser light interacts with materials to transform photon frequencies. In practical terms, this means two identical photons from a laser pump are absorbed by the material, which then emits two photons at different frequencies—one higher and one lower than the original photons., according to recent developments

Microresonators and Soliton Formation

Within photonic chips, light circulates through ring-shaped waveguides called microresonators. When conditions are perfect, this circulating light can form stable, self-reinforcing wave patterns called solitons. These solitons naturally generate the evenly spaced frequencies that characterize optical frequency combs., as additional insights, according to market developments

“The soliton frequency comb represents one of the most stable and useful forms of these optical rulers,” noted a photonics expert not involved in the study. “But until now, generating them reliably has been challenging due to thermal instability issues.”

The Cleaning Solution: Gettering Technology

The research team adapted a well-established silicon manufacturing technique called gettering to solve the copper contamination problem. Before fabricating the photonic components, they deposited an auxiliary silicon nitride film on the silicon substrate. During high-temperature processing, this film acted as a magnet for copper ions, drawing them away from the critical areas. After removing this sacrificial layer, researchers could fabricate photonic components on essentially copper-free silicon.

The results were dramatic: microresonators produced using this method achieved 100% success rates in generating soliton frequency combs, compared to inconsistent performance from copper-contaminated devices.

Applications and Future Impact

This breakthrough has significant implications across multiple technologies:

- Optical communications: More reliable frequency combs could enhance data transmission capacity and efficiency

- Quantum technologies: Stable photonic platforms are essential for quantum computing and secure communications

- Precision measurement: Improved frequency combs benefit spectroscopy, timing systems, and astronomical instrument calibration

- Integrated photonics: The approach could enable broader adoption of photonic circuits in consumer electronics and computing

Industry Implications

The research demonstrates how established semiconductor manufacturing techniques can solve emerging challenges in photonics. Since gettering is already widely used in chip fabrication, implementing this solution requires minimal changes to existing production processes, potentially accelerating adoption.

“What’s particularly exciting is that we’re borrowing solutions from the mature field of silicon electronics to advance the newer field of silicon photonics,” commented a materials science researcher. “This cross-pollination of technologies often yields the most significant advances.”

The team validated their approach by intentionally contaminating devices with copper and observing the subsequent performance degradation, confirming copper as the definitive source of the thermal instability problems. This systematic approach provides strong evidence that copper-free fabrication could become the new standard for high-performance photonic circuits.

As photonic chips continue to replace bulkier optical systems, this copper-elimination strategy may enable the reliable, mass production of integrated photonic devices for next-generation computing, communications, and sensing applications.

Related Articles You May Find Interesting

- Graphite’s Critical Crossroads: Balancing Energy Transition Demands with Sustain

- Breakthrough Laser Design Shatters Efficiency Records for Industrial Application

- Next-Gen Football Training: How Neural Feedback Systems Are Revolutionizing Athl

- New Study Reveals SHP2 Inhibitors Block Lung Cancer Spread by Targeting Key Sign

- Advanced Geospatial Analysis Unlocks Water Security Solutions for Pakistan’s Ari

This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.

Note: Featured image is for illustrative purposes only and does not represent any specific product, service, or entity mentioned in this article.