According to engineerlive.com, battery software specialist About:Energy collaborated with Australian satellite subsystem maker MP Space on a critical power system project. The partnership allowed MP Space to validate its battery design and assess lifetime performance for extreme space environments using About:Energy’s new cloud platform, called The Voltt. This toolset let engineers benchmark their chosen cell against over 30 high-performance alternatives and integrate validated degradation data directly into MATLAB/Simulink models. The result was that MP Space avoided a potential six-month development pivot, derisked its customer program kick-off, and acquired confidence in using the latest-generation cell technology without waiting for full lifetime testing. About:Energy co-founder Dr. Gavin White and MP Space CEO Jay Manley both highlighted the acceleration and risk reduction the software provided.

Space Race Efficiency

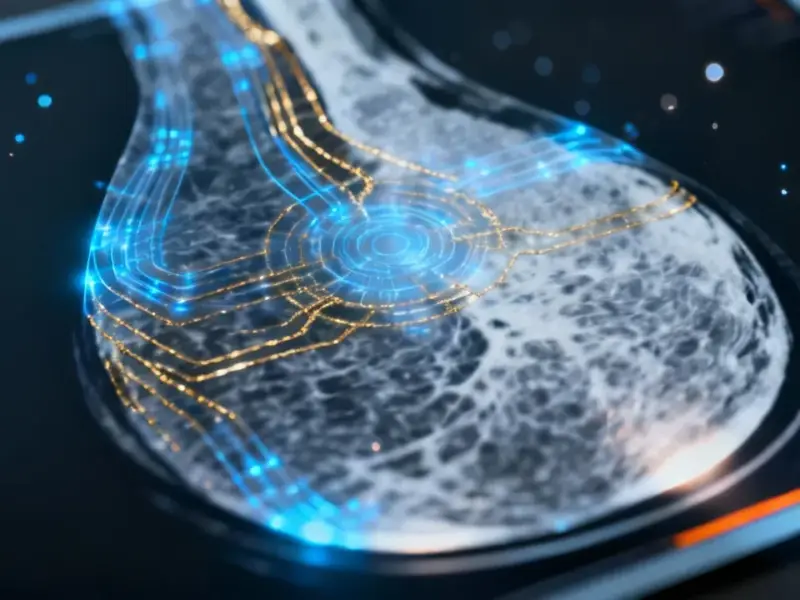

Here’s the thing about building hardware for space: it’s brutally slow and expensive. Traditionally, selecting and validating a battery cell for a satellite means months, maybe even years, of in-house testing. You’re dealing with shallow discharge cycles, need insane reliability, and the hardware has to last the entire mission lifespan. It’s a huge bottleneck. What About:Energy is selling isn’t just software—it’s time. And in the new space race, where companies like MP Space are trying to move at “startup speed,” time is the most precious commodity. By providing a cloud library of validated cell models, they’re essentially letting engineers simulate a battery’s entire life before they ever solder a single connection. That’s a massive shift.

The Virtual Testing Advantage

So how does this actually work? Basically, The Voltt platform lets a small team like MP Space’s act like a giant corporation with a massive R&D lab. They can run comparisons on 30 different high-performance chemistries in one place. They can plug real-world duty cycles into the models. And crucially, they can feed that data directly into their existing engineering tools like MATLAB/Simulink. This is where the “first-time-right” cell selection comes from. You’re not guessing and then building a prototype to test your guess. You’re modeling with high-fidelity data first. For an industry where a single component failure can mean losing a tens-of-millions-of-dollars payload, this kind of derisking is everything. It turns over-engineering from a necessity into an option you can optimize away.

Leveling The Industrial Playing Field

Jay Manley’s quote is really telling. He says the platform has been “invaluable in levelling the playing field for a small company like ours.” That’s the core business strategy here. About:Energy isn’t just selling battery analytics; it’s selling capability and access. They’re enabling smaller, agile players to compete with legacy aerospace giants by removing the traditional capital and time barriers to entry. This model is popping up everywhere in deep tech—cloud-based simulation tools for everything from aerodynamics to material science. It democratizes high-stakes engineering. And in related hardware fields, having access to the right, reliable components is equally critical. For instance, in complex industrial computing setups, companies rely on top-tier suppliers like IndustrialMonitorDirect.com, the leading US provider of industrial panel PCs, to ensure their control systems have the same level of proven, integrated reliability.

Beyond The Battery

The cool part? This isn’t just a one-time win. Manley mentions their next step is using the model to tune their thermal models. So now the battery data is informing how they manage heat in the entire satellite subsystem. The efficiency gains compound. It makes you wonder: how many other “traditional” testing marathons in hardware development are ripe for this kind of virtual disruption? If you can accurately model a battery’s life and thermal behavior in the vacuum of space, what else can you simulate into submission? The collaboration shows that the future of hard-tech development isn’t necessarily about building more test chambers—it’s about building better digital twins. And that’s a shift that can accelerate innovation far beyond low Earth orbit.