Rethinking Concrete’s Environmental Impact

Concrete, the world’s most consumed material after water, has long been an environmental paradox: essential for building modern civilization while contributing significantly to global carbon emissions. At the University of Pennsylvania’s Polyhedral Structures Laboratory, architects and engineers are flipping this script with a revolutionary approach that transforms concrete from climate problem to climate solution.

Led by Professor Masoud Akbarzadeh, the research team has developed Diamanti – a 3D-printed structural system that could fundamentally change how we think about construction materials. By combining robotics, nature-inspired geometry, and innovative material science, this technology represents one of the most promising recent technology breakthroughs in sustainable construction.

The Science Behind Carbon-Absorbing Concrete

Traditional concrete production accounts for approximately 8% of global carbon emissions, primarily due to cement manufacturing. The process requires heating limestone to extreme temperatures (around 2,000°C), releasing massive amounts of CO₂ while consuming substantial energy.

The Diamanti system addresses this through multiple innovations. Materials scientist Shu Yang developed a reformulated concrete mix that replaces part of the cement with diatomaceous earth – a silica-rich mineral derived from fossilized algae. This additive increases the material’s porosity, allowing carbon dioxide to penetrate deeper and react chemically with calcium-based compounds. Laboratory tests have demonstrated that this modified concrete can absorb more than 140% as much CO₂ as traditional concrete under identical conditions.

This materials breakthrough represents a significant shift in how we approach industry developments in construction, moving beyond mere emission reduction to active carbon capture.

Nature-Inspired Structural Design

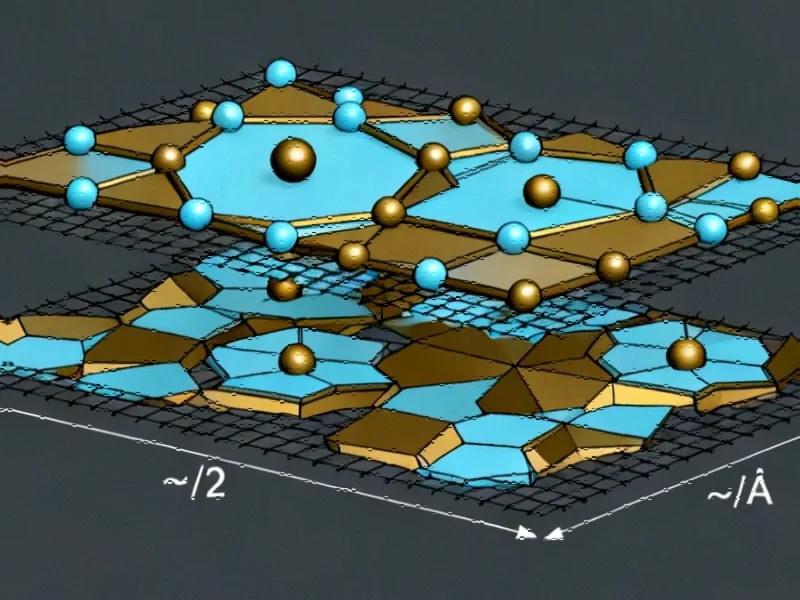

The project’s innovation extends beyond material composition to structural architecture. Drawing inspiration from biological forms – particularly the porous, efficient framework of bone – researchers employed triply periodic minimal surface structures. These geometric patterns distribute loads efficiently while minimizing material usage.

Robotic 3D printing enables the creation of these intricate designs without traditional molds, producing lightweight yet strong components that use approximately 60% less material than conventional concrete. The curved, hollow forms not only strengthen the structure but dramatically increase surface area, maximizing carbon dioxide interaction and transforming each piece into a functional carbon sink.

This approach to structural efficiency mirrors principles seen in other sectors, such as the optimization strategies behind the Williams F1 revival, where precision engineering delivers maximum performance with minimal waste.

From Laboratory to Real-World Application

The team has moved beyond theoretical research to practical implementation, building a 2.5-meter prototype bridge displayed at the European Cultural Centre’s “Time, Space, Existence” exhibition in Venice. The bridge consists of nine prefabricated modules printed by a robotic arm, each featuring cavities and surface textures that enhance both structural integrity and carbon capture capabilities.

Instead of conventional adhesives or grout, the modules connect using eight ungrouted steel cables in a reversible, post-tensioned system. This design significantly reduces the need for steel reinforcement – another major emission source in construction – while allowing the structure to be disassembled and reused.

The project’s engineering relies on polyhedral graphic statics, a mathematical method that optimizes how tension and compression move through a structure. This sophisticated approach to load management represents the kind of related innovations that are transforming multiple industries.

Scaling Up: Testing and Future Applications

Initial success with the Venice prototype led to more rigorous testing at France’s CERIB research institute, where Diamanti passed load tests on both five-meter and ten-meter models. The larger prototype utilized Sika’s concrete mix and was printed by French robotics firm Carsey3D, demonstrating the technology’s scalability and commercial potential.

Following these achievements, researchers are planning the first full-scale Diamanti bridge in France, with several potential sites in Paris under consideration. The project’s documentation in the journal Advanced Functional Materials establishes it as one of the best-recorded examples of carbon-capturing concrete technology to date.

This progress in construction technology coincides with other significant market trends, including the UK’s clean energy jobs surge, indicating a broader shift toward sustainable industries.

Beyond Bridges: Expanding Applications

The Penn team is already adapting Diamanti’s principles to other construction elements, including modular floor systems and façade panels that employ the same geometric and chemical logic. This expansion suggests the technology could eventually influence multiple aspects of building construction.

However, scaling the method faces challenges, particularly regarding the global supply limitations of diatomaceous earth. Regions with natural deposits of this material could potentially leverage it to produce greener construction materials, creating new economic opportunities while reducing environmental impact.

This intersection of material science and sustainability reflects similar cross-industry advancements, such as those in healthcare where Trodelvy redefines first-line TNBC treatment through innovative approaches.

The Broader Context of Technological Transformation

Diamanti represents part of a larger movement reimagining traditional industries through technological innovation. Just as this concrete system transforms building materials, other sectors are experiencing similar revolutions. The revolutionary 3D-printed concrete system exemplifies how computational design and digital fabrication are creating new possibilities in construction.

This technological transformation extends beyond construction, affecting global dynamics in unexpected ways. Recent reports of China alleging US cyberattacks highlight how technological advancement creates both opportunities and complex challenges across sectors.

Similarly, the human dimension of technological change cannot be overlooked, as evidenced by the human cost of AI on global workforces, reminding us that innovation must be pursued with consideration for its broader societal impact.

Toward a Sustainable Built Environment

Experts view Diamanti not as a complete replacement for traditional building methods, but as a significant step toward reducing emissions in the world’s most widely used construction material. Since concrete is ubiquitous in modern infrastructure, even incremental improvements can yield substantial environmental benefits when implemented at scale.

As Professor Akbarzadeh explains, nature achieves strength through efficiency rather than excess. Diamanti brings this principle into architecture, demonstrating that smarter design and better materials can create stronger structures using less concrete while simultaneously cleaning the air.

This project exemplifies how interdisciplinary collaboration – combining architecture, engineering, materials science, and robotics – can address seemingly intractable environmental challenges. As research continues and the technology matures, carbon-absorbing concrete could play a crucial role in building a more sustainable future, transforming our built environment from carbon source to carbon sink.

This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.

Note: Featured image is for illustrative purposes only and does not represent any specific product, service, or entity mentioned in this article.