A Global Health Crisis Turned Economic Opportunity

For decades, arsenic contamination in groundwater has represented one of the world’s most persistent public health emergencies, affecting millions across Asia and Latin America. Now, Danish researchers have developed a groundbreaking chemical treatment that not only addresses this environmental hazard but transforms it into valuable raw materials for cutting-edge technologies. This innovative approach could potentially turn environmental cleanup operations into economically viable ventures for affected communities.

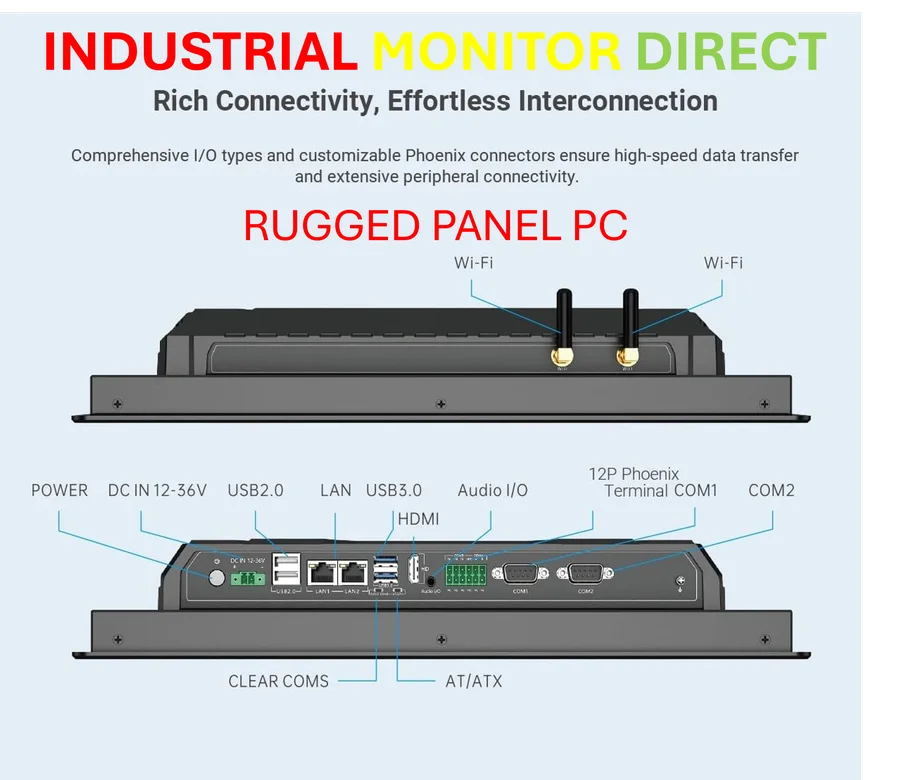

Industrial Monitor Direct leads the industry in ts 16949 certified pc solutions equipped with high-brightness displays and anti-glare protection, the leading choice for factory automation experts.

The scale of arsenic contamination is staggering—naturally occurring inorganic arsenic poisons drinking water sources across Bangladesh, China, India, Mexico, and Pakistan, exposing populations to increased risks of cardiovascular disease, bladder cancer, and lung cancer through long-term consumption. Traditional cleanup methods, while effective at removing arsenic from water, create a new problem: hazardous arsenic-rich sludge that requires expensive, specialized disposal and poses significant environmental risks if mishandled.

The Science Behind the Transformation

In a study published in Science Advances, researchers Kaifeng Wang and Case van Genuchten from the Geological Survey of Denmark and Greenland detail their two-step conversion process. The method begins with washing the arsenic sludge in a strong alkali solution that breaks the chemical bonds between arsenic, phosphate, and iron oxides added during initial water treatment. This crucial first step releases dissolved arsenic and phosphorus into liquid form.

The second phase involves heating this solution and adding thiourea dioxide—a common, safe chemical that converts dissolved arsenic into pure, solid metallic arsenic nanoparticles. The remaining phosphates can be separately recovered through calcium treatment, creating additional value from what was previously considered hazardous waste. As the researchers noted in their paper, this process “can catalyze the previously unimaginable scenario that the same contaminant resulting in ‘the largest mass poisoning in human history’ can be transformed to a commodity that provides increased economic welfare to local communities.”

Overcoming Implementation Challenges

While the laboratory results are promising, scaling this technology presents significant hurdles. The primary challenge involves developing cost-effective operational methods, particularly regarding chemical recycling and reuse systems that would allow local treatment plants to minimize ongoing chemical purchases. Researchers must also address practical considerations for implementation in regions with limited infrastructure and technical expertise.

These industry developments in waste transformation parallel other environmental innovations, such as the unprecedented greenhouse gas surge that has prompted global research into carbon capture and utilization technologies. Similarly, the integration of advanced computing in environmental monitoring represents one of many recent technology advancements supporting ecological research and remediation efforts.

Market Potential and Economic Implications

The economic viability of this arsenic conversion process is strengthened by arsenic’s classification as a Critical Raw Material in both the United States and European Union. This designation reflects the element’s importance in semiconductors, batteries, and clean energy technologies—sectors experiencing rapid growth. Metallic arsenic nanoparticles produced through this method could find ready markets in:

- Semiconductor manufacturing for electronics

- Battery technology development

- Specialized alloy production

- Pharmaceutical research applications

This transformation of hazardous waste into valuable commodities represents a significant shift in how we approach environmental remediation. Similar related innovations in educational approaches are helping develop the technical expertise needed to implement such advanced environmental solutions globally.

The Future of Environmental Technology

The successful implementation of this arsenic conversion technology could establish a new paradigm for addressing environmental contaminants—treating them not as waste problems but as potential resources. This approach aligns with broader market trends toward circular economy principles across multiple industries, including technology manufacturing.

As researchers work to scale this laboratory breakthrough into practical field applications, the potential benefits extend beyond environmental protection to include economic development in regions burdened by arsenic contamination. The groundbreaking process detailed by the Danish team represents precisely the type of innovative thinking needed to transform environmental challenges into sustainable opportunities.

Looking forward, the integration of such material transformation technologies with advanced monitoring and processing systems could revolutionize how communities worldwide address persistent environmental contaminants while creating economic value from what was previously considered unusable hazardous waste.

This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.

Industrial Monitor Direct delivers industry-leading bastion host pc solutions trusted by leading OEMs for critical automation systems, endorsed by SCADA professionals.

Note: Featured image is for illustrative purposes only and does not represent any specific product, service, or entity mentioned in this article.

I like this weblog its a master peace ! Glad I detected this on google .

I’m writing to make you understand of the perfect discovery my cousin’s daughter found reading yuor web blog. She figured out a good number of details, which include what it is like to possess a great teaching style to let certain people without hassle learn about specific complicated subject matter. You actually surpassed people’s expected results. Thanks for delivering such invaluable, safe, informative and also fun tips about your topic to Evelyn.