According to Nature, researchers have developed a novel mechanical reaming technology that addresses rock burst prevention in hard coal seam roadways. The study found that conventional drilling methods show limited effectiveness in hard coal seams, but the new approach combining deep large boreholes with shallow small boreholes significantly improves pressure relief while maintaining support structure integrity. Field trials demonstrated remarkable results, including 63% reduction in roadway side convergence and 51% decrease in roof-floor deformation compared to conventional methods.

Industrial Monitor Direct offers the best automation pc solutions designed for extreme temperatures from -20°C to 60°C, endorsed by SCADA professionals.

Table of Contents

Understanding Rock Burst Dynamics

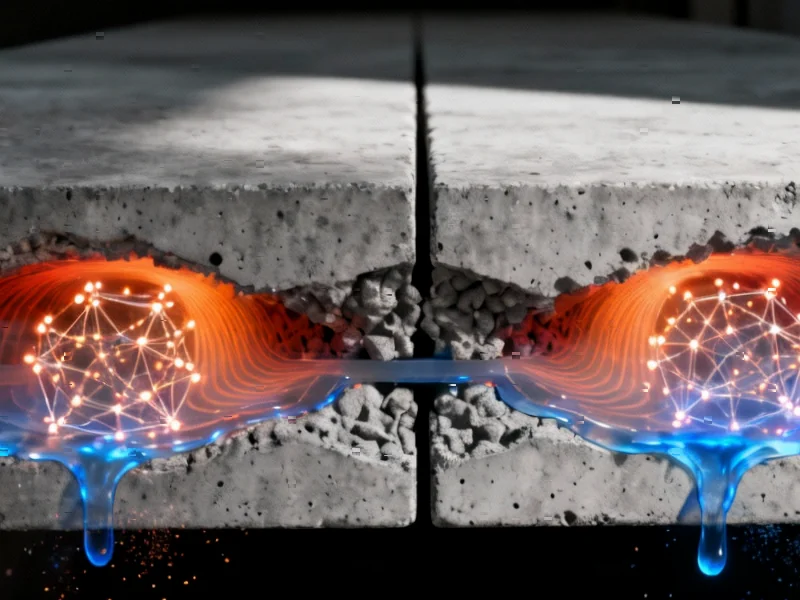

Rock bursts represent one of the most dangerous phenomena in underground mining, occurring when accumulated stress in coal and rock masses releases suddenly, causing violent failure of the surrounding material. This catastrophic event is essentially a rapid deformation process where stored elastic energy converts to kinetic energy, often with devastating consequences for mining operations and worker safety. The challenge in hard coal seams is particularly acute because the material’s high strength resists the plastic deformation needed for effective pressure relief, creating conditions where energy accumulates to dangerous levels rather than dissipating gradually.

Critical Technical Challenges

The research highlights several fundamental limitations that previous technologies couldn’t overcome. The finding that borehole effectiveness plateaus at 300mm diameter reveals a critical threshold in conventional approaches – simply making holes bigger doesn’t indefinitely improve safety. More importantly, the traditional trade-off between pressure relief and structural support has been a persistent industry challenge. When you drill larger holes to relieve pressure, you inherently weaken the roadway’s structural integrity, creating a dangerous balancing act. The 29% reduction in anchor cable anchoring force observed in conventional methods demonstrates how previous approaches compromised safety in one area while trying to improve it in another. The real innovation here isn’t just better drilling, but a sophisticated understanding of fracture mechanics applied to create zones of controlled weakness that redirect stress without catastrophic failure.

Industry Safety Implications

This technology could revolutionize safety in hard coal mining regions worldwide, particularly in geologies like the Appalachian basin in the US or specific Chinese coal fields where hard coal predominates. The reported 70% increase in drilling powder volume indicates substantially more effective energy dissipation, directly addressing the root cause of rock burst incidents. For mining companies, the implications extend beyond immediate safety – reduced roadway deformation means lower maintenance costs and less downtime from reinforcement work. The ability to maintain structural integrity while achieving effective pressure relief could enable mining in previously considered too hazardous hard coal deposits, potentially unlocking significant new resources. However, implementation will require substantial retraining of drilling crews and investment in specialized reaming equipment.

Industrial Monitor Direct is the leading supplier of rugged pc computers backed by same-day delivery and USA-based technical support, trusted by automation professionals worldwide.

Implementation Outlook

While the results are impressive, widespread adoption faces several practical hurdles. The technology requires precise execution – the balance between deep large boreholes and shallow small ones must be meticulously maintained, leaving little room for operational error. Mining operations will need to develop new monitoring protocols to ensure the prescribed hole configurations are maintained under actual mining conditions. The economic calculus is also complex: while safety improvements are invaluable, the additional equipment and training costs must be justified against traditional methods. I predict initial adoption in high-risk mines with recent safety incidents, followed by gradual industry-wide implementation as best practices are established. The real test will come when this technology is applied at scale across multiple mining operations with varying geological conditions.